We will print your label directly from your computer. This printing method does not require the production of printing forms (clichés), which significantly reduces the cost of the label and the production time.

VARIABLE IMAGE AND INFORMATION

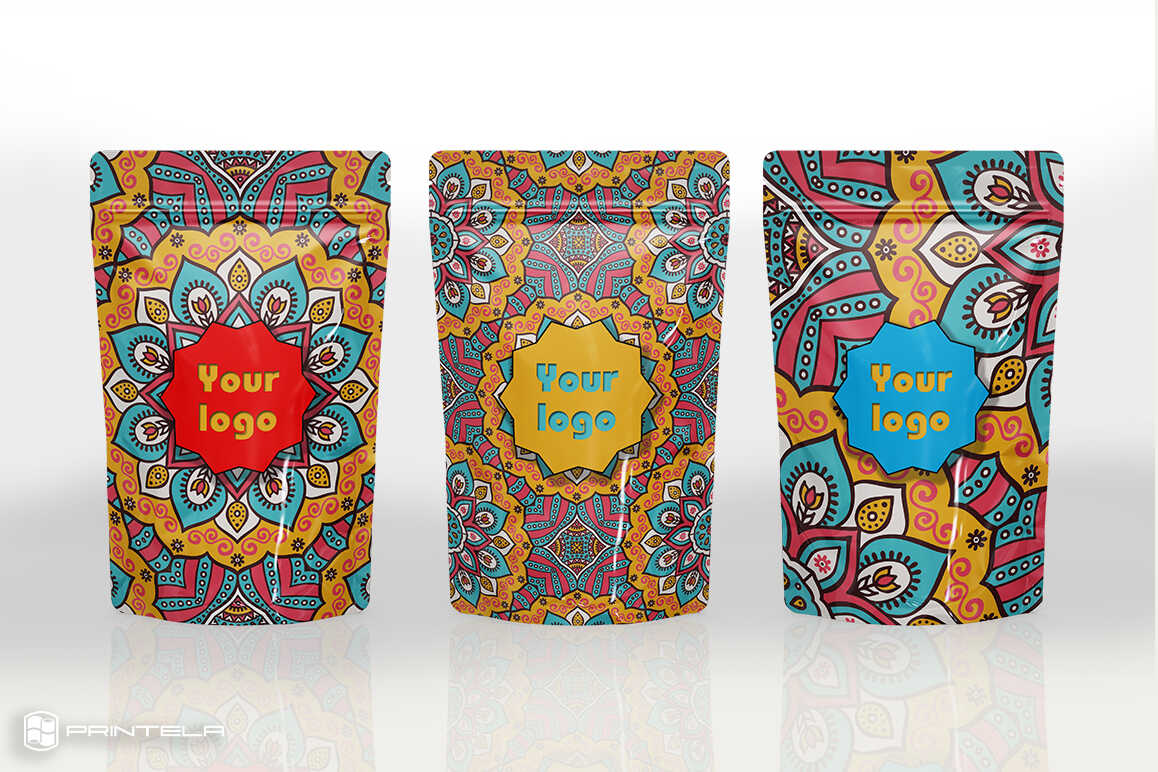

One of the most important features that separates digital printing from traditional printing is the ability to print unique text and images on each pouch at no extra cost. This allows you to run marketing campaigns linked to the brand’s social network.

Also, the innovative HP SmartStream Mosaic technology lets you create an unlimited number of differently designed labels! Each label can be unique without the need for a team of creative designers.

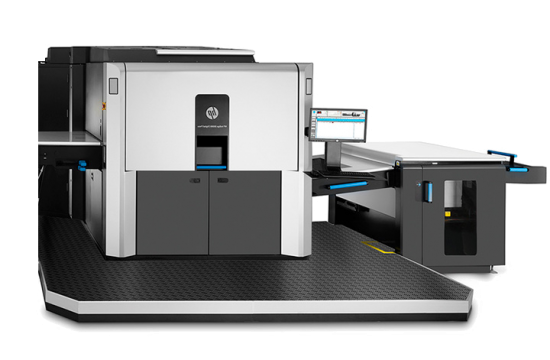

Our company has successfully installed two of the most modern digital printers in the world, HP Indigo, which opens new possibilities for your labels and packaging choices. Bringing even the most impossible projects to life.

The ever changing designs and information on your labels, serial numbers, QR codes, security marks, help brands create unique product labels. We can digitally print on any flexible material 12-450 μm thick.

With the equipment we use, our colour matching rate is 97%. We guarantee that by choosing one specific colour code, you will always get the same shade.

With no minimum quantities, digital printing allows you to produce unique, personalized labels for different user groups while also letting you quickly update information and develop seasonal products to test the market. Ultimately saving you money and reducing waste.

DIFFERENCES BETWEEN DIGITAL AND TRADITIONAL PRINTING METHODS

| CRITERIA | DIGITAL PRINTING | TRADITIONAL PRINTING METHOD |

|---|---|---|

| Order turnaround time | Pre made pouches – from 1 week. Flow wrap film – from 1 week. Labels – from 2 business days. Overall a quicker response to market changes. | 6 – 12 weeks |

| Order volume | From 1 unit. to… | Suitable for printing large quantities. From 10,000 and up. |

| Resources | Smaller quantities, less frozen funds, less storage space. | Necessary to invest in large quantities of packaging and labels, to store them. |

| Cost of print plates (clichés) and equipment for printing | No printing plates or additional set up fees. | Additional costs for preparation of printing forms and equipment for each layout. |

| Customisation | Each pouch and label can be unique at no extra cost. Can print personalized packaging and labels at the same time, which have been adapted to different user groups and seasons. Ideal for product testing, promotions. | Flexible packaging and labels of the same design are printed in large quantities at a time. |

When you need to print large copies of labels, we use flexographic printing technology.

In this way, you can quickly and efficiently print on a variety of materials – paper, foil, film (PP, PE, PET, BOPP, etc.) and textiles (nylon, polyester, satin, cotton).

BENEFITS OF FLEXOGRAPHIC PRINTING

Flexographic printing uses printing forms and ink with bright colours, gloss effects and is known for its resistance to mechanical damage.